| Item | Description | Material |

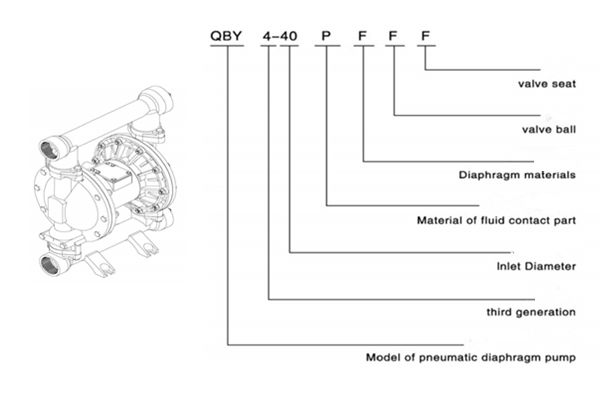

| 1 | Model | QBY |

| 2 | In/Outlet | 06=1/4” 10=3/8” 15=1/2” 20=3/4” 25=1” 40=1.5” 50=2” 80=3”100=4” |

| 3 | Center Black | AL-Aluminum PP-Polypropylene SS-Stainless Steel |

| 4 | Pump Body | PP-Polypropylene KV -PVDF PM-POM AL-Aluminum SS-Stainless Steel 304 LL-Stainless Steel 316 AC-Cast Iron TF -PTFE |

| 5 | Diaphragm | TF -PTFE ST -Santoprene HY-Polyether Rubber VT-VITON BN-NBR EP-EPDM GE-Geolast PU-Polyurethane |

| 6 | Valve Ball | TF -PTFE ST -Santoprene HY-Polyether Rubber VT-VITON BN-NBR EP-EPDM SS-Stainless Steel 304 LL-Stainless Steel 316 CM-Ceramic |

| 7 | Valve Seat | TF -PTFE ST -Santoprene HY-Polyether Rubber VT-VITON BN-NBR EP-EPDM SS-Stainless Steel 304 LL-Stainless Steel 316 PP-Polypropylene |

What is air operated diaphragm pump?

QBY4 is JK's new developed model diaphragm pump series which is also the 4 generation,it has the virtue of long life span and nonstop operation,not only it can convey some uneasy flowed medium,which the merits the merits of self priming pump,diving pump,shield pump,slurry pump and impurity pump ,etc.

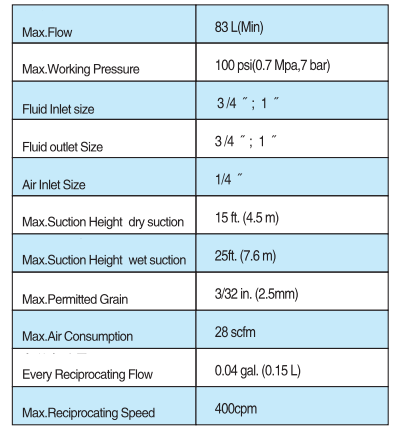

1. It is unnecessary to pour the drawing water,the suction lift reaches 3m height ,the delivery lift reaches of 70m length and the export pressure 6 bar.

2. Wide flow and good performance,The diameter allowed to pass the max grain reaches 10mm;the damage is very less to the pump while exhausting the slurry and impurity.

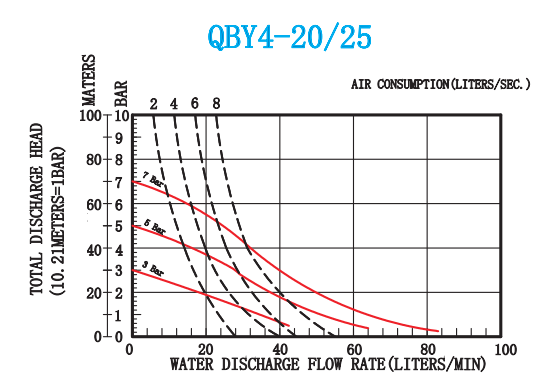

3. The delivery lift and flow can pass the pneumatic valve open to realize the step less adjustment (the pneumatic pressure adjustment is between 1-7bar).

4. This pump has no rotary parts and no bearing seals.The diaphragm pump will completely separate the exhausted medium and pump running parts,working medium.The conveyed medium cannot be leaked outside.Thus it will not cause the environmental pollution and human body safely dangerous while exhausting the toxin and flammable or corrosive medium.

5. No electricity,it is safe and reliable while using in the flammable and explore places.

6. It can be soaked in medium.

7. It is convenient to use and reliable to work,Only open or close the gas valve body while staring or stopping.Even if no medium operation or pausing suddenly for long time because of accident matters,the pump will not be damaged caused by this.Once over loading ,the pump will automatically stop and possesses the self protection function.When the load recovers normally,it also can start automatically.

8. Simple structure and less wearing parts.This pump is simple in structure,installation and maintenance.The medium conveyed by the pump will not touch the matched pneumatic valve and coupling lever .etc.Not like other kinds pumps,the performance will drop down gradually because of the damaged of damages of rotor,gear and vane,etc.

9. It can transmit the adhesive liquid(the viscosity is below 10000 centipoises).

10. This pump needn't the oil lubricant,even if idling,it has no any influence to the pump,this is a characteristic of this pump.

What Makes an QBY so Special?

An diaphragm pumps has a lot of advantages over other pump designs. Below we list out some of the advantages of QBY pumps over against other pump types.

Advantages include:

No Electricity: These pumps operate via compressed air. This means that they can be used in environments where an electrical supply is not suitable in hazardous areas.

Simplicity: Without requiring complicated wiring, and no need to have an electrical control, QBY’s are easy to install and operate. In fact, they are much easier to use than many other pump types.

Run Dry: QBY's pumps can run dry without damaging the pump or cause any issues. Some other pump types will always need to stay primed and not run dry or they will either damage the whole pump or some of the parts, resulting in a costly rebuild.

Features and advantages:

1.Light weight,Easy installation and maintenance;

2.Performs on -demand in remote locations;

3.Extremely portable for multi -locations;

4.Little air waste and pulsation, high capacity and performance;

5.Can run dry without pump damage;

6.No air lubrication necessary;

7.The fluid transport is extremely extensive,Can convey acid,alkali,strong organic solvents and other fluid;

8.High temperature resistant, corrosion resistant;

Appication Industry:

Chemical industry: acids, alkalis, solvents, suspended solids, dispersion systems.

Petrochemical industry: heavy oil, grease, mud, sludge, etc.

Coating industry: resins, solvents, colorants, paints, etc.

Daily chemical industry: detergents, shampoos, lotions, emulsions, hand creams, surfactants.

Ceramic industry: mud, porcelain slurry, lime slurry, clay slurry.

Mining industry: coal slurry, magma, mud, mortar, lubricants, etc.

Water treatment: lime slurry, soft sediment, sewage, chemicals, waste water.

Food industry: liquid semi-solid, chocolate, brine, vinegar, syrup, rape oil, soybean oil, honey.

Beverage industry: yeast, syrup, concentrate, gas-liquid mixture, wine, fruit juice, corn syrup, etc.

Pharmaceutical industry: solvents, acids, alkalis, plant extracts, ointments and other pharmaceutical materials.

Paper industry: binders, resins, paints, inks, pigments, hydrogen peroxide, etc.

Electronics industry: solvents, electroplating solutions, cleaning solutions, nitric acid, waste acids, corrosive acids, polishing solutions.

Textile industry: dye chemicals, resins, glues, etc.

Construction industry: cement slurry, ceramic tile binder, rock slurry, ceiling finish, etc.

Automobile industry: polishing emulsion, oil, coolant, automobile primer, oil emulsion, varnish, varnish additives, degreasing liquid, paint, etc.

Furniture industry: adhesives, varnishes, dispersion systems, solvents, colorants, white wood glue, epoxy resins, starch adhesives.

Metallurgy, casting and dyeing industry: metal slurry, hydroxide and carbonized slurry, dust washing slurry, etc