MODEL INDENTIFICATION:

JKH - W - 40 - SK - 5 - 5 - V - F - Ti

1 2 3 4 5 6 7 8 9

| 1 | MODEL | JKH |

| 2 | BASE SHAPE | F-Square Y-Circle W-Groove Extemal Standard Type / Special Customized |

| 3 | IN/OUTLET(mm) | 32-50*32 40-50*40 50-65*50 |

| 4 | SPECIFIC GRAVITY | SK-1.1 SP-1.4 |

| 5 | POWER | 1-1HP, 2-2HP, 3-3HP, 5-5HP, 7.5-7.7HP, 10-10HP |

| 6 | FREQUENCY | 5-50HZ 6-60HZ |

| 7 | O-RING | E-EPDM V-VITON |

| 8 | MATERIAL | F-FRPP P-PVDF |

| 9 | SHAFT MATERIAL | 4-SUS304 6-SUS316 Ti-Ti |

Detailed Description:

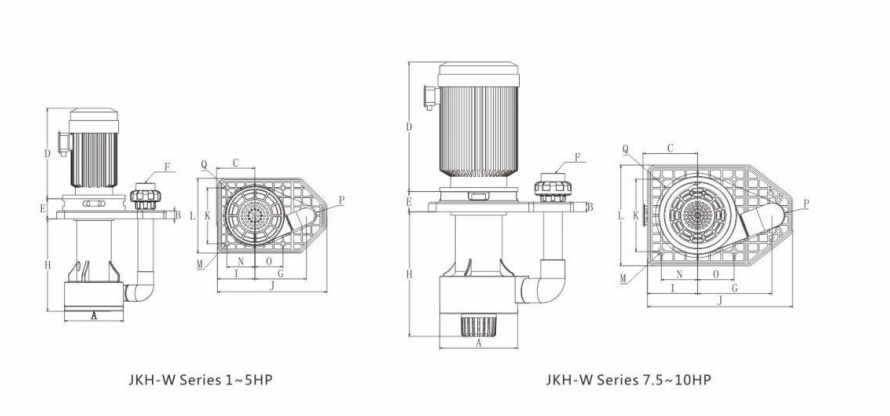

VERTICAL IMMERSIBLE PUMPS are simple in design, efficient in performance, and self-priming when immersed in solution. Constructed completely of FRPP with PVDF wear ring, or FRPP with PVDF impeller where in contact with the solution, this pump is suitable for pumping, agitating, filtering, or circulating acid and alkaline solutions, abrasive fluids, and other corrosive solutions up to 120℃ degrees maximum temperature.

Standard motors are 3 phase and totally enclosed fan cooled, with 2 part epoxy coating for additional corrosion resistance. A rigid, solid stainless steel rotor/drive shaft with an oversized bearing is employed to minimize shaft alignment problems, while allowing for quick and easy bearing replacement when required. The three phase motors are shipped unwired.

A standard air purge/vent screw assembly in the bottom motor housing extends the life of the bottom motor bearing when utilizing minimal 5 psi air to create a positive displacement. An optional ceramic sealing sleeve is available for added corrosion resistance in preventing fumes and condensables from contacting the metallic shaft or impeller insert.

JK's vertical pumps-JKH series are versatile, easy to install, and require a minimal amount of tank space, thus saving valuable floor space.

Features:

• Easy Installation

• Chemical Resistant

• Extended Pump Lengths

• Corrosion Resistant Epoxy Paint

• Single Phase, 115V Models, 3 phase 220-415V

• Positive Displacement Air Purge Vent

Recommended Applications:

• Plating

• Etching

• Filtering

• Wet Processing

• Waste Treatment

• Wet Fume Scrubbing

• Transfer/Recirculation Pumping

• Cleaning solutios

• Deliver acid

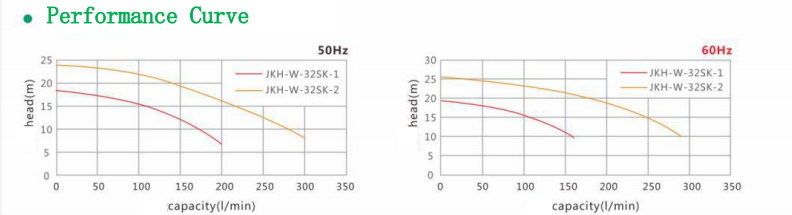

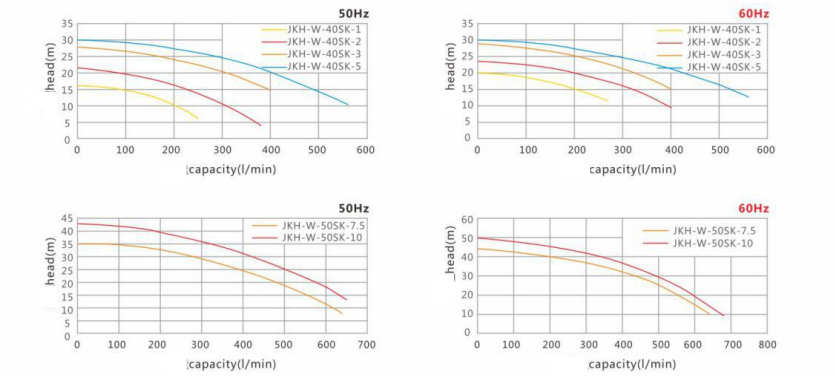

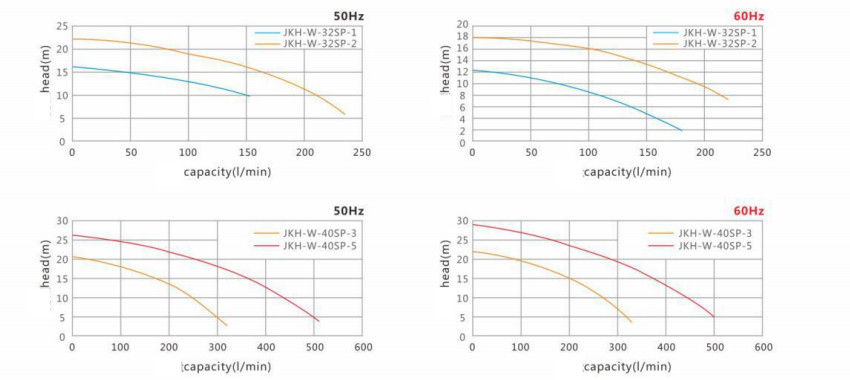

| MODEL | SPEC | SG | IN/OUT | POWER | POLE | 50HZ | 60HZ | WEIGHT(kg) | ||

| HEAD(m) | FLOW(L/min) | HEAD(m) | FLOW(L/min) | |||||||

| JKH-W | 32SK-1 | 1:1 | 50*32 | 1 | 2 | 18 | 200 | 17 | 160 | 17 |

| JKH-W | 40SK-1 | 1:1 | 50*40 | 1 | 2 | 18 | 210 | 16.5 | 170 | 19.2 |

| JKH-W | 32SK-2 | 1:1 | 50*40 | 2 | 2 | 26 | 290 | 25 | 260 | 20.5 |

| JKH-W | 40SK-2 | 1:1 | 50*40 | 2 | 2 | 26 | 380 | 24 | 300 | 21.6 |

| JKH-W | 40SK-3 | 1:1 | 50*40 | 3 | 2 | 28 | 400 | 27 | 350 | 24.6 |

| JKH-W | 50SK-5 | 1:1 | 50*50 | 5 | 2 | 32 | 560 | 30 | 520 | 35.7 |

| JKH-W | 50SK-7.5 | 1:1 | 50*50 | 7.5 | 2 | 44 | 640 | 38 | 620 | 55.8 |

| JKH-W | 50SK-10 | 1:1 | 50*50 | 10 | 2 | 46 | 700 | 43 | 690 | 60.5 |

| JKH-W | 32SP-1 | 1:4 | 50*32 | 1 | 2 | 19 | 180 | 16 | 150 | 17.6 |

| JKH-W | 40SP-1 | 1:4 | 50*40 | 1 | 2 | 17 | 190 | 16 | 160 | 19.2 |

| JKH-W | 32SP-2 | 1:4 | 50*40 | 2 | 2 | 26 | 260 | 23 | 240 | 21.6 |

| JKH-W | 40SP-3 | 1:4 | 50*40 | 3 | 2 | 28 | 330 | 25 | 320 | 24.6 |

| JKH-W | 50SP-5 | 1:4 | 50*50 | 5 | 2 | 28.5 | 540 | 30 | 500 | 35.7 |

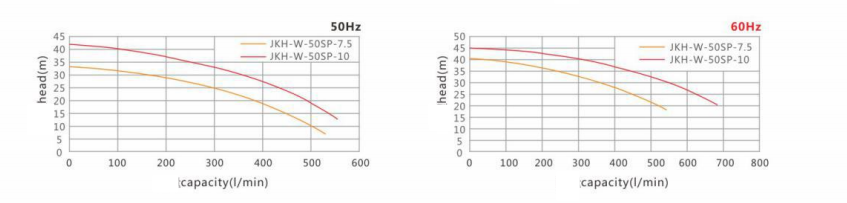

| JKH-W | 50SP-7.5 | 1:4 | 50*50 | 7.5 | 2 | 41 | 620 | 38 | 580 | 55.8 |

| JKH-W | 50SP-10 | 1:4 | 50*50 | 10 | 2 | 45 | 680 | 43 | 650 | 60.5 |

Vertical pump -JKH series Features:

1. JKH series vertical pumps are manufactured from higher grade raw material and can be define to FRPP,PVDF for customer selection;The pump power range from 0.75kw to 7.5kw;

2. There are more type designed base shape of choice to your needs,for example square,circle,groove extemal,standard type,special customized;The weight of the pump is lighter,more acid and alkali resistant,and better meet the needs of different industries;

3.Vertical acid and alkaline resistant pump:JKH series widely used in chemical or water recirculation,Fame scrubbers/waste treatment,PCB plating solutions,Wet processing,cleaning solutios,Deliver acid;

4.Airless vertical pumps;

5.Vertical pumps can run-dry without damage to vapor seal;

6.Beside,extra vapor seal can also stop the acid vapor to reach the bearing;

7.The seal plate made from high purity aluminum oxide ,excellent in wear resistanting ,hrat resistanting and chemicals resisting;

8.The motor shaft is designed and install from internally (no extension, no joint) to ensure stability and better performance as well to enable the motor to have longer lifespan;

9.It is designed to inside tank ;however ,the installation instruction should be followed and can be fitted together with filter system;

10.For corrosive environment, it is recommended to use Titanium bolt and nuts and Epoxy paint on motor body to prolong motor lifespan;different brands motor of choice to your needs,for example:QUCHI,TECO and ABB;

11.Max Operating Temperature: FRPP 75℃; PVDF:100℃;

12.JK has been certified with ISO9001:2015,CE certification,Production&sales intellectual property management system certification;

13.1 year warranty;

Recommended Applications:

• Plating

• Etching

• Filtering

• Wet Processing

• Waste Treatment

• Wet Fume Scrubbing

• Transfer/Recirculation Pumping

• Cleaning solutios

• Deliver acid