New launched high flow vertical pump-MVF

JK's new launched vertical pumps-MVF series are simple in design which produces high flow and efficient in performance, and self-priming when immersed in the solution. With a double impeller design and no seals to leak or bushings or bearings to wear, this high flow vertical pump can run dry without damage while requiring little or no maintenance.

Constructed completely of FRPP or PVDF wherein contact with the solution, these pumps are suitable for pumping, agitating, filtering, or recirculating acid or alkaline corrosive solutions over the entire 0-14 pH range up to180°F maximum temperature.

Standard motors are three phase and totally enclosed fan cooled, with two part epoxy coating for additional corrosion resistance. A rigid, solid stainless steel rotor/drive shaft with an oversized bearing is employed to minimize shaft alignment problems while allowing for quick and easy bearing replacement when required. The three phase motors are shipped unwired.

A standard air purge/vent screw assembly in the bottom motor housing extends the life of the bottom motor bearing when utilizing minimal 5 psi air to create a positive displacement.

New launched vertical pump Features

• FRPP or PVDF Construction

• No Metal Contact

• Chemical Resistant

• Self-Priming When Immersed

• Run Dry Capability Without Damage

• Flows to 560 L/min

Recommended Applications:

• Sump Pumping

• Transfer Pumping

• Recirculation Pumping

• Plating Solution Filtering

• Fume Scrubbing

• Waste Treatment

• Eductor Systems

• Other corrosive solutions

MODEL INDENSIFICATION

M -V -F - 40 - SK - 1 - 5 - E - F - 4 - 4

1 2 3 4 5 6 7 8 9 10 11

| 1 | Model | MVF |

| 2 | Type | Vertical pump |

| 3 | F-High flow P-High Pressure | |

| 4 | In/Outlet | 32-32*32 40-40*50 50-50*50 |

| 5 | SG | SK-1.1 SP-1.4 |

| 6 | Power | 1-0.75kw 2-1.5kw 3-2.2kw 5-3.75kw |

| 7 | Frequency | 5-50HZ 6-60HZ |

| 8 | O-ring | E -EPDM V -VITON |

| 9 | Material | F-FRPP P-PVDF |

| 10 | Shaft Length | 4-417 3-300 |

| 11 | Shaft Material | 4-SUS304 6-SUS316 T-Ti |

What are the application industries of vertical pumps?

1. Used in the electroplating industry for the transmission of various acid and alkaline liquids;

2. Used in the PCB manufacturers for the PCB etching equipment;

3. Used in the environmental protection industry for the wasre-gas purification tower and wastewater treatment ;

4. The vertical pump is specialized for transfer and circulation of various liquids from containers, sumps and tanks.

5. The materials used in the pump body are FRPP, CFRPP, CPVC and PVDF materials, which have high temperature resistance and corrosion resistance.

What is different between horizontal and vertical pumps?

Appearance: the vertical pump is standing while the horizontal pump is lying horizontally;

In terms of choice, most people will like to use horizontal centrifugal pumps, mainly because horizontal pumps are simple, easy to repair and maintain. The vertical centrifugal pump is troublesome to maintain and needs to be lifted every time it is repaired. Moreover, the long shaft pump needs to replace the sliding bearing under the liquid for a long time. If it is not replaced, the possible consequence is that the centrifugal force of the shaft becomes larger and larger, causing the shaft runout value to increase. If it is not replaced in time, it will cause a mechanical accident. And ensure absolute horizontal installation during installation.

Connection form: vertical pumps are superimposed and connected from bottom to top, and horizontal pumps are arranged on the base vertically. Vertical pumps are commonly called pipeline pumps such as vertical pipeline centrifugal pumps. The motor and pump body are connected by sub-ports; horizontal pumps are connected The shaft device is connected to the motor and needs to be aligned regularly.

Floor space: vertical pumps occupies a small area but [horizontal pumps] take up a large area. The vertical pump set occupies a smaller area than horizontal pumps, and it does not necessarily require a foundation; the horizontal pump set has a base, so basis.

Maintenance difficulty: Vertical pumps are difficult to maintain. For example, the upper part of the impeller must be removed before it can be performed. For horizontal pumps, it is relatively easy. For example, the IS pump can be repaired by removing the inlet pipe.

Advantages of vertical centrifugal pump

1. Vertical centrifugal pumps are mostly used for working conditions that can not be installed in underground tanks. Or because there is no open space on-site for the horizontal centrifugal pump, you can only use the vertical centrifugal pump on the tank.

2. If an ordinary horizontal pump (not a self-priming pump) has a poor self-priming ability, it is impossible to pump the medium from the tank below. Therefore, horizontal pumps and vertical pumps are not comparable.

3. Installation: the vertical pump is integrally connected, which is easy to install; while the horizontal pump needs to be adjusted for accuracy after installation.

| Model | SG | Max.Temperature(℃) | 50HZ | 60HZ | Power(kw) | |||

| FRPP | PVDF | Max.Head(m) | Max.Capacity(L/min) | Max.Head(m) | Max.Capacity(L/min) | |||

| MVF-32SK-1 | 1.1 | 75℃ | 100℃ | 19 | 200 | 19 | 160 | 0.75 |

| MVF-32SK-2 | 1.1 | 75℃ | 100℃ | 24 | 300 | 25.2 | 290 | 1.5 |

| MVF-40SK-1 | 1.1 | 75℃ | 100℃ | 16 | 250 | 20 | 280 | 0.75 |

| MVF-40SK-2 | 1.1 | 75℃ | 100℃ | 22.3 | 380 | 24 | 400 | 1.5 |

| MVF-40SK-3 | 1.1 | 75℃ | 100℃ | 28 | 400 | 29 | 400 | 2.2 |

| MVF-50SK-5 | 1.1 | 75℃ | 100℃ | 30 | 560 | 30 | 560 | 3.75 |

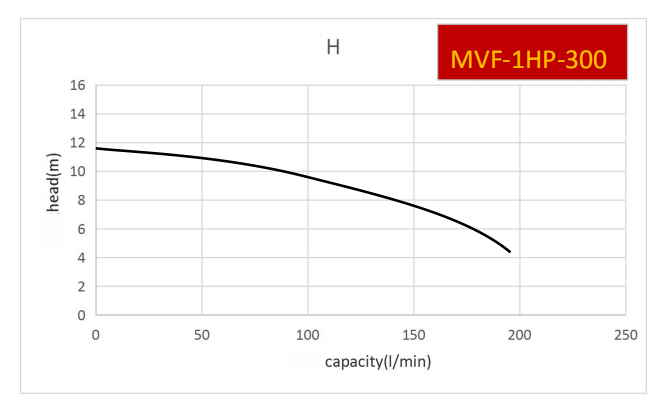

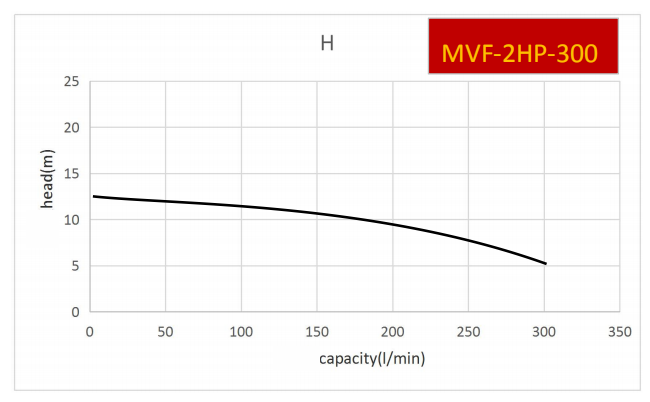

Performance Curve:

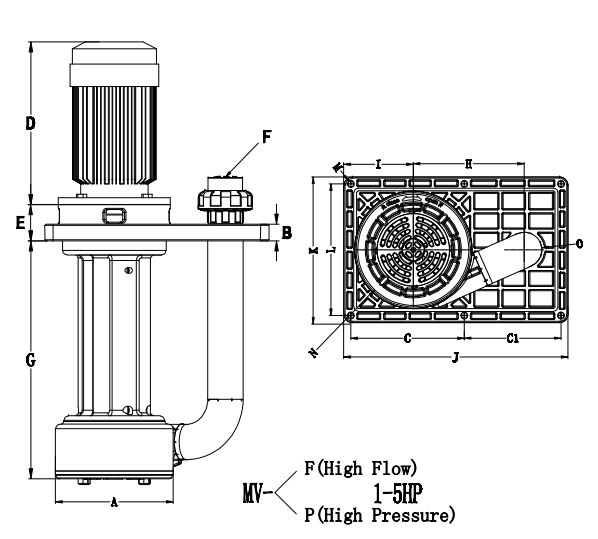

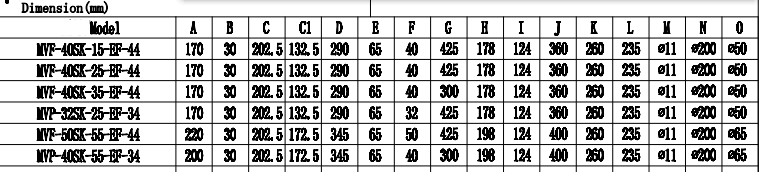

DIMENSION:

1.New launched: MVP series for high flow performance;

2.MVF series vertical pumps are manufactured from higher grade raw material and can be defined to FRPP, PVDF for customer selection;

3.Vertical acid and alkaline resistant pump: MVF series widely used in chemical or water recirculation, Fame scrubbers/waste treatment, PCB plating solutions, Wet processing, cleaning solutions, Deliver acid;

4.Airless vertical pumps;

5.Vertical pumps can run-dry without damage to vapour seal;

6.Beside, extra vapour seal can also stop the acid vapour to reach the bearing;

7.The seal plate made from high purity aluminum oxide, excellent in wear-resistant, heat resistant and chemicals resisting;

8.The motor shaft is designed and install from internally (no extension, no joint) to ensure stability and better performance as well to enable the motor to have a longer lifespan;

9.It is designed to inside tank; however, the installation instruction should be followed and can be fitted together with filter system;

10.For corrosive environment, it is recommended to use Titanium bolt and nuts and Epoxy paint on the motor body to prolong motor lifespan; different brands motor of choice to your needs, for example QUCHI, TECO and ABB;

11.Max Operating Temperature: FRPP 75℃; PVDF:100℃;

12.1-year warranty;

Recommended Applications:

• Sump Pumping

• Transfer Pumping

• Recirculation Pumping

• Plating Solution Filtering

• Fume Scrubbing

• Waste Treatment

• Eductor Systems

• Other corrosive solutions